Galvanized Steel Building: Durable & Economical Building Material

Discover the advantages of galvanized steel building materials for your construction. Corrosion-resistant, strong, and cost-effective. Learn more here!

Galvanized steel building materials have become the top choice in the modern construction industry.

This material offers a perfect combination of strength, durability, and cost efficiency. With its unique galvanization process, this steel can withstand corrosion and various extreme weather conditions.

This article will discuss in depth about galvanized steel, its advantages, and its applications in various types of buildings. Whether you’re a contractor, architect, or project owner, understanding this material will help you make the right decisions for your construction project.

1. A Brief Introduction to Galvanized Steel Building Materials

Galvanized steel building materials have revolutionized the construction industry with their excellence and reliability. This material is the result of technological innovation that combines the strength of steel with zinc protection through the galvanization process. This process involves coating steel with molten zinc, creating a strong and durable metallurgical bond.

The history of galvanized steel can be traced back to the 18th century when a French chemist, Paul Jacques Malouin, first discovered the galvanization process. However, its commercial use only began in the 19th century. Since then, galvanization technology has continued to evolve, producing increasingly high-quality and efficient products.

The galvanization process itself consists of several important stages. First, the steel is thoroughly cleaned to remove dirt, oil, and rust. Then, the steel is dipped in an acid solution to activate its surface. After that, the steel is immersed in a bath containing molten zinc at a temperature of about 450°C. The reaction between steel and zinc forms a very strong and durable zinc-iron alloy layer.

The composition of galvanized steel consists of steel as the core material and a zinc layer on the outside. This zinc layer not only serves as a physical barrier against corrosive elements but also provides cathodic protection. This means that even if the zinc layer is scratched or damaged, zinc will continue to protect the underlying steel from corrosion.

In the construction industry, galvanized steel is available in various shapes and sizes. From steel sheets, pipes, to structural profiles such as beams and columns. This diverse availability allows the use of galvanized steel in various applications, from roofing to building frames.

Quality standards for galvanized steel building materials are regulated by various international institutions. The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) are two of the bodies that set standards for the quality and thickness of galvanized coatings. These standards ensure that galvanized steel used in construction meets the necessary safety and durability requirements.

Technological developments continue to drive innovation in galvanized steel production. Currently, manufacturers can produce galvanized steel with more consistent zinc layer thickness and better surface quality. In addition, modern galvanization techniques also allow coating on steel with complex shapes, expanding the possibilities of application in modern architectural design.

2. Advantages of Galvanized Steel Building Materials

Galvanized steel building materials offer various advantages that make them the primary choice in the construction industry. Here are some of the main advantages of this material:

- Corrosion Resistance The most significant advantage of galvanized steel is its resistance to corrosion. The zinc layer formed during the galvanization process provides double protection. First, as a physical barrier that prevents oxygen and water from reaching the steel surface. Second, zinc acts as a sacrificial anode, which means zinc will corrode first, protecting the underlying steel. This corrosion resistance is especially valuable in aggressive environments such as coastal areas or industrial zones.

- Long-Term Durability Galvanized steel has a very long service life. With minimal maintenance, this material can last up to 50 years or more in normal environments. Even in more aggressive environments, galvanized steel can still last for several decades. This durability not only saves replacement costs but also reduces operational disruptions due to repairs or renovations.

- Strength and Toughness Although coated with zinc, galvanized steel retains the strength and toughness of its base steel. This means the material can withstand heavy loads and is resistant to impacts. This strength allows the use of galvanized steel in various structural applications, from building frames to bridges.

- Cost Efficiency Although the initial cost of galvanized steel may be higher compared to regular steel, in the long run, this material is far more economical. Low maintenance costs, long service life, and minimal replacement needs make galvanized steel a very profitable investment.

- Environmentally Friendly Galvanized steel is an environmentally friendly material. The zinc used in the galvanization process is 100% recyclable, and the steel itself can also be recycled without losing its quality. Moreover, the durability of galvanized steel means more efficient use of resources in the long term.

- Aesthetics Galvanized steel has a distinctive and attractive metallic appearance. The shiny surface and unique texture can add aesthetic value to buildings. Additionally, galvanized steel can be painted to provide a more diverse appearance without sacrificing its corrosion protection.

- Ease of Inspection The quality of the galvanized coating can be easily inspected visually. The thickness of the zinc layer can also be measured with simple tools, facilitating quality control in the field.

3. Some Common Applications of Galvanized Steel Buildings

Galvanized steel building materials have wide applications in the construction industry. Here are some common uses of this material:

- Roofs and Walls Galvanized steel is often used for roofs and walls of buildings, especially for commercial and industrial structures. Galvanized steel sheets can be formed into various roof and wall profiles, offering a combination of strength, weather resistance, and aesthetics. This use is very common in warehouses, factories, and shopping centers.

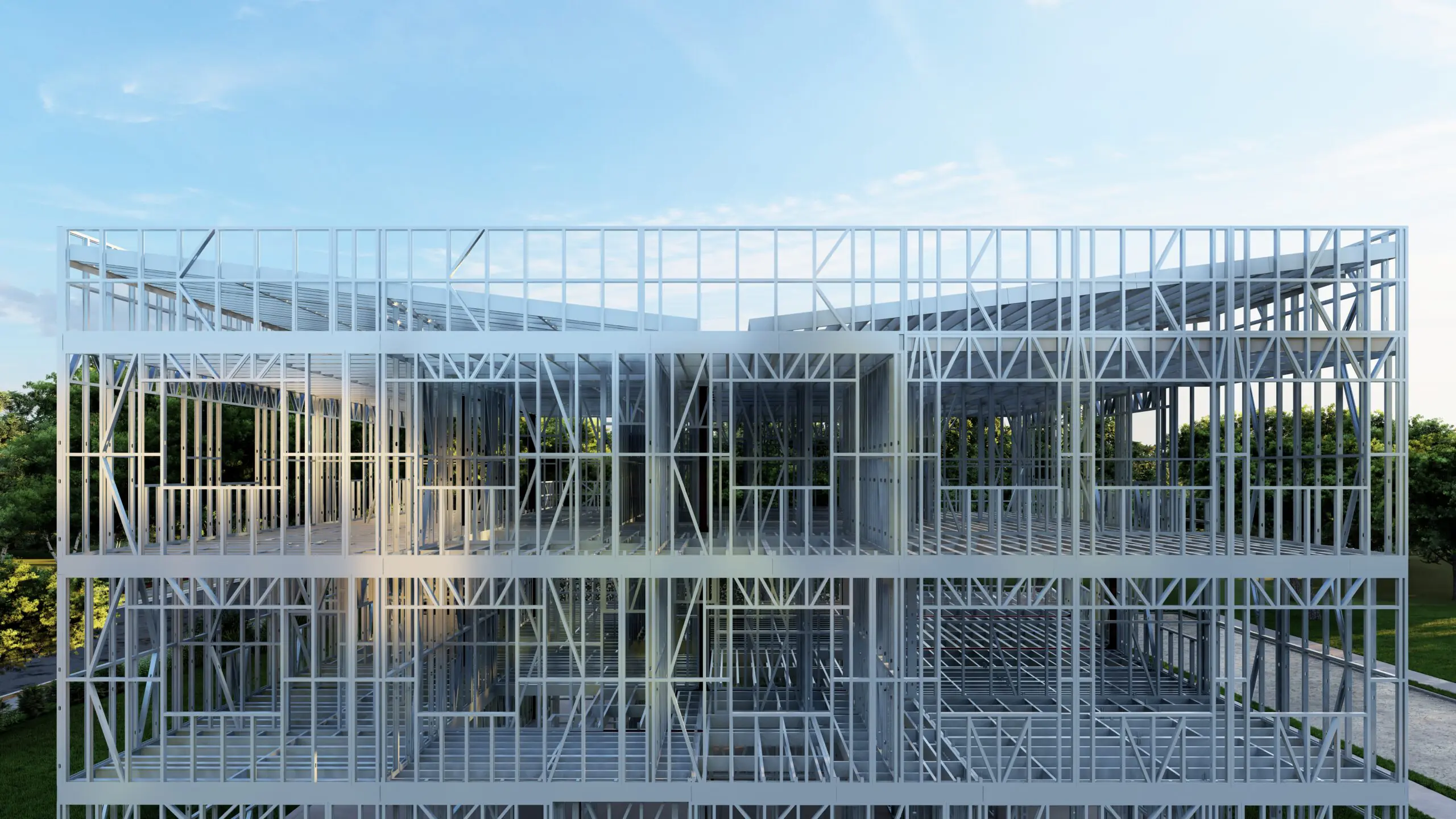

- Structural Frames In light steel construction, galvanized steel is the primary choice for structural frames. Profiles such as C-channels and Z-purlins made of galvanized steel are used to form roof, wall, and floor frames. The strength and corrosion resistance of this material ensure long-term structural integrity.

- Drainage Systems Gutters, downspouts, and other drainage components are often made of galvanized steel. The corrosion resistance of this material is crucial in this application, given the constant exposure to water and moisture.

- Fences and Railings Galvanized steel is a popular choice for fences and railings, both for residential and commercial applications. This material offers the strength and durability required for security, while providing an attractive appearance.

- Stairs and Platforms In industrial and commercial buildings, stairs and platforms are often made using galvanized steel. The corrosion resistance and strength of this material make it ideal for applications that require high safety.

- Towers and Poles Transmission towers, light poles, and other tall structures often use galvanized steel. Weather and corrosion resistance are crucial for structures constantly exposed to outdoor elements.

- Bridges and Infrastructure In bridge construction and other infrastructure, galvanized steel is used for various components, including beams, railings, and reinforcement systems. The long-term durability of this material is very valuable in infrastructure applications that require a long service life with minimal maintenance.

- Greenhouses and Agricultural Structures Galvanized steel is often used in the construction of greenhouses and other agricultural buildings. Resistance to moisture and agricultural chemicals makes this material ideal for these challenging environments.

4. Conclusion

Galvanized steel building materials have proven themselves as superior solutions in the modern construction industry. With a combination of strength, durability, and cost efficiency, this material offers significant benefits for various types of construction projects. Exceptional corrosion resistance and long service life make galvanized steel a smart long-term investment.

The diversity of galvanized steel applications, from roofing to heavy infrastructure, demonstrates the flexibility and reliability of this material. Moreover, the environmentally friendly nature and ease of recycling of galvanized steel align with sustainable construction trends that are increasingly important in the modern era.

With the continued development of galvanization technology and innovations in structural design, the future of galvanized steel in the construction industry looks very promising. Whether for small or large-scale projects, galvanized steel building materials will continue to be the primary choice for construction professionals who value quality, durability, and efficiency.

Post Comment