Cold-Formed Steel Structures: Advantages and Applications in Construction

Discover the advantages and applications of cold-formed steel structures in building construction. Cold-formed steel offers efficiency and flexibility.

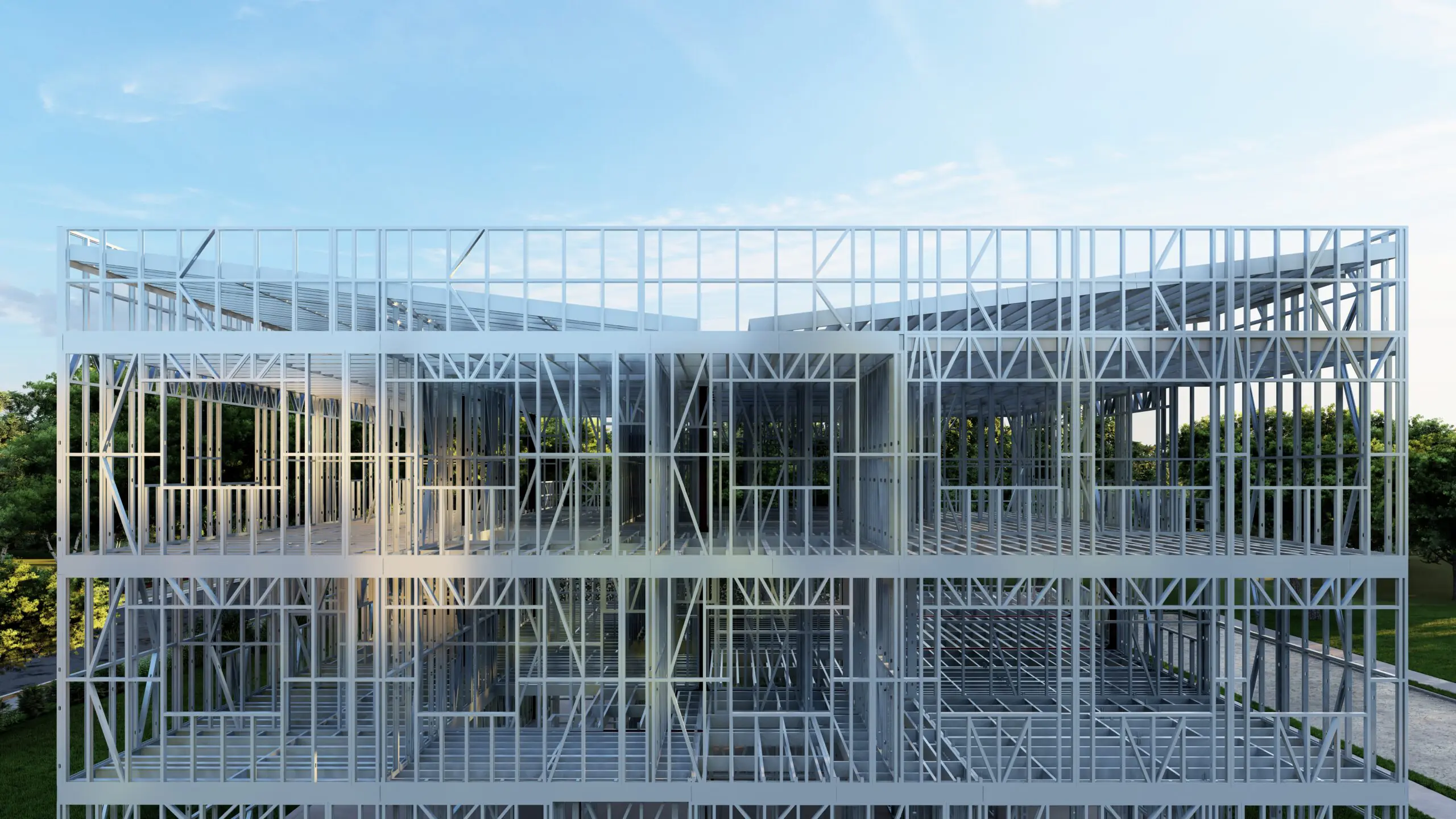

Cold-formed steel structures represent a significant innovation in modern construction. By using high-quality steel shaped at room temperature through a cold-forming process, these structures offer efficiency and flexibility not found in other materials.

This article delves into the advantages of cold-formed steel structures, their applications in various types of buildings, and how this technology can benefit your construction projects.

1. Overview of Cold-Formed Steel Structures

Cold-formed steel structures refer to construction systems that use steel formed at room temperature through a cold-forming process. This steel is usually processed into various profile shapes, which are then assembled into building structures. This process makes cold-formed steel lighter and easier to install compared to conventional structural steel that requires heating and shaping at high temperatures.

One of the main advantages of cold-formed steel structures is their ability to produce profiles with very tight tolerances. With the cold-forming process, steel can be manufactured to precise sizes and shapes, allowing for more complex and detailed structural designs. This also reduces material waste and increases production efficiency.

Additionally, cold-formed steel structures have good corrosion resistance, making them suitable for various environmental conditions, including damp or potentially corrosive areas. The strength and durability of cold-formed steel allow for its use in a wide range of applications, from partition walls to main building structures.

The use of cold-formed steel is becoming increasingly popular due to its design flexibility and ease of installation. This steel can be produced in various shapes and sizes and can be easily cut and shaped on-site as needed. This makes cold-formed steel ideal for construction projects that require a lightweight and efficient structural solution.

2. The Advantages of Cold-Formed Steel in Construction

One of the greatest advantages of cold-formed steel structures is their high strength-to-weight ratio. This structure offers the same strength as conventional steel but with much less weight. This reduces the load on foundations and allows for less material use, which in turn lowers overall construction costs.

Another advantage is the ease of installation. Cold-formed steel structures are often pre-fabricated in factories and then shipped to the project site in the form of modules or panels. This minimizes the time required for on-site construction and reduces the need for a large workforce. The installation process is also quicker compared to traditional construction methods, allowing for faster project completion.

Cold-formed steel also has good fire resistance properties. Although not an absolute fireproof material, this structure can provide adequate protection against fire under certain conditions. This makes it a safe choice for various types of buildings, including those requiring high fire safety standards.

Furthermore, cold-formed steel structures are environmentally friendly. The production process generates less waste compared to other construction methods, and the steel itself can be fully recycled at the end of its service life. This makes it a more sustainable option in the long run.

3. Cold-Formed Steel Applications: From Residential Homes to Commercial Buildings

Cold-formed steel structures are highly versatile and can be used in a wide range of applications, from residential homes to commercial buildings. In residential projects, this steel is often used for partition walls, roof framing, and other internal structures. Its ability to be manufactured in various shapes and sizes allows for flexible and innovative designs, which are often challenging to achieve with other materials.

In the commercial sector, cold-formed steel is used in the construction of office buildings, shopping centers, and industrial facilities. The main advantage in these applications is its ability to support large structural loads with relatively light weight. This allows for larger and column-free interior spaces, which is highly valuable in commercial space design.

Additionally, cold-formed steel is also used in the construction of bridges, stations, and various other infrastructures. The advantages of cold-formed steel in terms of strength and design flexibility make it an ideal choice for large projects requiring innovative and efficient structural solutions.

4. Conclusion

Cold-formed steel structures offer various advantages that make them an attractive option in modern construction. With high strength, light weight, and ease of installation, these structures allow for more flexible and efficient designs. Additionally, their corrosion resistance and environmental friendliness make them a sustainable solution for various construction applications.

The use of cold-formed steel is expanding across different types of projects, from residential to commercial and infrastructure. Its ability to provide innovative and effective structural solutions keeps cold-formed steel as a top choice for construction professionals seeking to enhance the efficiency and quality of their projects.

By understanding the benefits and applications of cold-formed steel structures, you can make better decisions for your construction projects and leverage this technology for optimal results.

Post Comment