Key Considerations in High-Bay Warehouse Construction

Learn about crucial factors in high-bay warehouse construction, including advantages, differences from conventional warehouses, and latest lighting technologies.

High-bay warehouses are becoming an increasingly popular storage solution in this modern era. With their ability to optimise vertical space, these warehouses offer various advantages compared to conventional warehouses.

This article will delve deep into the concept of high-bay warehouses, their differences from traditional warehouses, and important considerations in their construction.

From efficient space utilisation to the latest lighting technologies, you’ll gain comprehensive insights to understand why high-bay warehouses are becoming the primary choice for many companies in managing their inventory.

1. What is a high-bay warehouse?

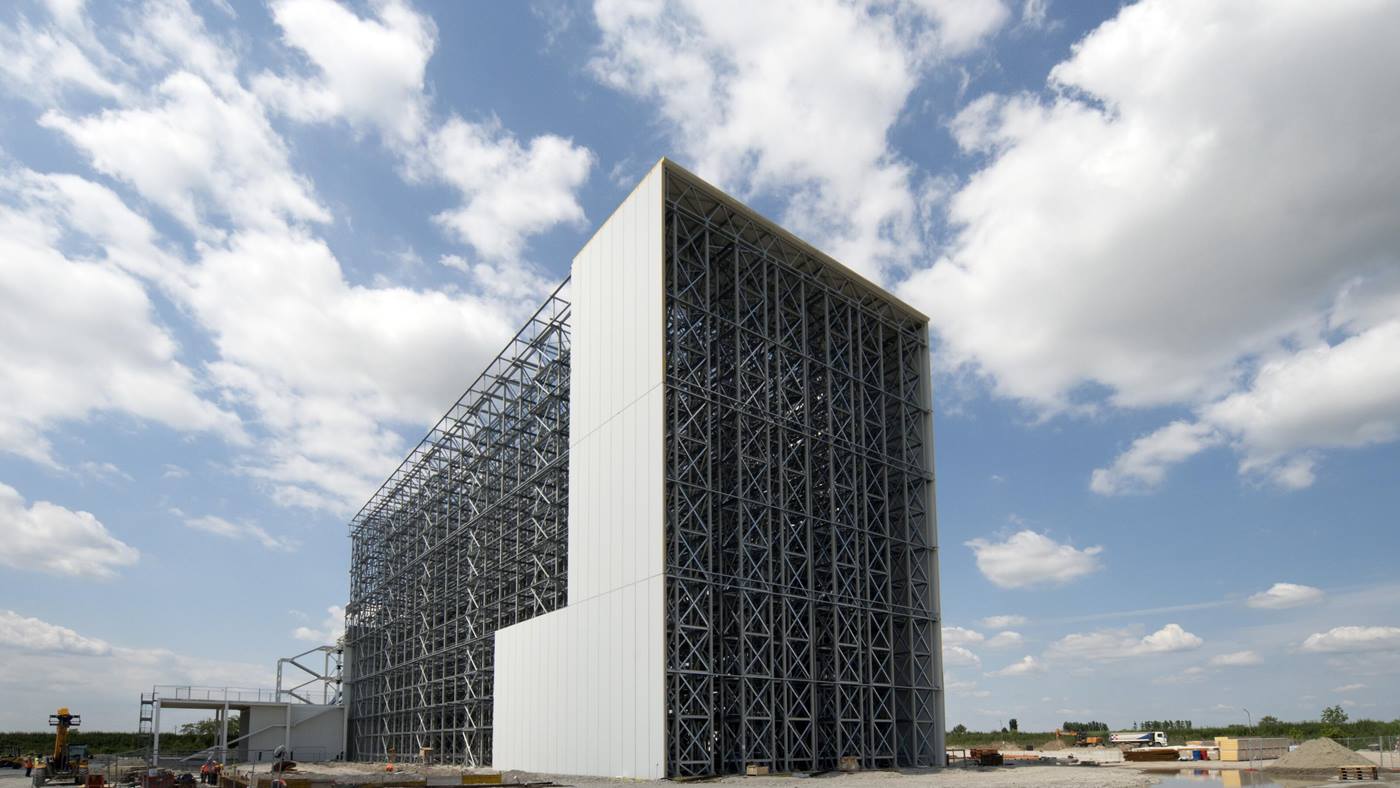

A high-bay warehouse is a modern storage facility designed to maximise the use of vertical space. Unlike conventional warehouses, high-bay warehouses have a much greater height, typically exceeding 12 metres. This concept was developed to meet the need for greater storage capacity in limited land areas.

The structure of a high-bay warehouse consists of tall racks that can reach heights of up to 50 metres or more. These racks are specially designed to withstand heavy loads and are equipped with automatic or semi-automatic retrieval systems. Narrow aisles between the racks allow for the operation of specialised forklifts or automated cranes to access stored goods.

One of the hallmarks of a high-bay warehouse is the use of advanced technology in its management. An integrated Warehouse Management System (WMS) allows real-time monitoring of inventory and optimization of space usage. Additionally, high-bay warehouses are often equipped with temperature and humidity control systems to maintain the quality of stored goods.

The construction of a high-bay warehouse requires careful planning and complex technical considerations. A strong foundation is necessary to support the large structural load. Ventilation and fire suppression systems must also be specially designed to reach high areas. Lighting becomes another important aspect, given the extreme height of the space.

In its operations, high-bay warehouses often use Automated Storage and Retrieval Systems (AS/RS). This system consists of cranes that move along the aisles, picking up and placing goods with high precision. The use of this technology not only increases efficiency but also reduces the risk of workplace accidents.

Although the initial investment to build a high-bay warehouse is quite large, the long-term efficiency it offers often makes it an economical choice. Optimal utilization of vertical space means more goods can be stored in the same area, reducing the need for expensive additional land.

2. Differences between high-bay warehouses and conventional warehouses

High-bay warehouses and conventional warehouses have significant differences in various aspects, from structural design to day-to-day operations. A deep understanding of these differences is important to determine the type of warehouse that best suits business needs.

First, the most striking difference is height. Conventional warehouses typically have heights between 6 to 12 metres, while high-bay warehouses can reach heights of 30 metres or more. This height difference affects many other aspects of warehouse design and operations.

In terms of storage capacity, high-bay warehouses are far superior. By utilising vertical space, high-bay warehouses can store up to three times more goods compared to conventional warehouses with the same floor area. This makes high-bay warehouses an ideal solution for urban areas where land is limited and expensive.

The storage system also differs significantly. Conventional warehouses typically use standard racks and traditional forklifts for goods handling. In contrast, high-bay warehouses use specialised rack systems designed for extreme heights and are often equipped with AS/RS (Automated Storage and Retrieval System).

The level of automation is another major difference. Conventional warehouses rely more on human labour for day-to-day operations. High-bay warehouses, on the other hand, often integrate advanced automated technologies, including robots, automated conveyors, and computerised warehouse management systems.

Operational efficiency also differs greatly. With automated systems, high-bay warehouses can operate 24/7 with minimal human intervention, increasing productivity and reducing errors. Conventional warehouses, although more flexible in some aspects, generally have lower efficiency and are more prone to human error.

Safety aspects also have different approaches. Conventional warehouses require workers to frequently climb to heights, increasing the risk of accidents. High-bay warehouses, with their automated systems, reduce this need, although they require special safety procedures for system maintenance at heights.

Initial and operational costs also differ significantly. Building a high-bay warehouse requires a much larger initial investment due to structural complexity and the technology used. However, in the long run, operational efficiency and better space utilization can result in significant cost savings.

Flexibility is an area where conventional warehouses may have an advantage. Conventional warehouses are easier to modify or restructure to accommodate changing needs. High-bay warehouses, with their complex structures and automated systems, are less flexible in this regard.

Lastly, environmental impact also differs. High-bay warehouses, although consuming more energy for their automated system operations, generally have a smaller carbon footprint per unit of stored goods due to higher space efficiency and reduced internal transportation needs.

3. Advantages of high-bay warehouses

High-bay warehouses offer several significant advantages compared to conventional warehouses. Here’s a detailed explanation of their main advantages:

Efficient Use of Space:

One of the biggest advantages of high-bay warehouses is their ability to optimise vertical space usage. By utilising height, these warehouses can store more goods in the same floor area. This is especially valuable in locations where land is limited or expensive. This space efficiency also means lower cost per storage unit in the long run.

Increased Storage Capacity:

As a direct result of efficient space usage, high-bay warehouses offer far greater storage capacity. This allows companies to manage larger inventories without needing to expand the warehouse area horizontally. This increased capacity also enables companies to better manage seasonal demand fluctuations or business growth.

Automation:

High-bay warehouses are often equipped with advanced automation systems. These include automated storage and retrieval systems (AS/RS), automated conveyors, and robots. This automation increases the speed and accuracy of warehouse operations, reduces human error, and allows for 24/7 operations. This results in significant productivity improvements and reduction in labor costs in the long term.

Safety:

Although working at heights is potentially dangerous, high-bay warehouses actually offer a higher level of safety. With automated systems, the need for workers to climb to dangerous heights is significantly reduced. Additionally, advanced security systems and strict standard operating procedures are easier to implement in this highly structured environment.

Flexibility:

Although their physical structure is less flexible compared to conventional warehouses, high-bay warehouses offer flexibility in terms of inventory management. Advanced warehouse management systems allow for quick and efficient arrangement and retrieval of goods. This allows companies to quickly adapt to changes in demand or inventory strategies.

4. Popular High Bay Lighting Technologies

Proper lighting is crucial in high-bay warehouse operations. Here are some popular lighting technologies used:

LED:

LED (Light Emitting Diode) lights have become the primary choice for modern high-bay warehouse lighting. LEDs offer high energy efficiency, long lifespan (up to 100,000 hours), and excellent light quality. They can also be instantly turned on and are compatible with advanced lighting control systems. LEDs generate minimal heat, reducing the load on warehouse cooling systems.

Metal Halide:

Metal halide lamps have long been used in high-bay warehouses because they produce bright white light with good color reproduction. They are more efficient than traditional high-pressure sodium lamps. However, they have a long warm-up time and shorter lifespan compared to LEDs. Metal halide is still used in some warehouses, especially those that haven’t been upgraded to LED technology.

High-Pressure Sodium:

High-pressure sodium (HPS) lamps produce characteristic yellow-orange light and are very efficient in terms of lumens per watt. They have a long lifespan and relatively low initial cost. However, their color reproduction is poor, which can be a problem in warehouse operations that require accurate color identification. HPS also has long warm-up and cool-down times.

Induction:

Induction lamps use an electromagnetic field to produce light, providing a very long lifespan (up to 100,000 hours) and minimal maintenance. They offer instant start-up and good light quality. However, their initial cost is high and their energy efficiency is not as good as modern LEDs. Induction lamps can be a good choice for warehouse areas that are difficult to access where lamp replacement is rarely done.

5. Conclusion

The construction of high-bay warehouses represents a significant step forward in storage technology and inventory management. By optimally utilizing vertical space, high-bay warehouses offer an effective solution to storage challenges in the modern era where land is increasingly limited and expensive.

The advantages of high-bay warehouses, from increased storage capacity to high levels of automation, make them an attractive choice for many companies. However, the decision to invest in a high-bay warehouse must be carefully considered, taking into account factors such as high initial costs, specific business needs, and long-term growth projections.

Proper lighting technology also plays a crucial role in the efficiency and safety of high-bay warehouse operations. With the rapid development of LED technology, warehouse lighting is becoming more energy-efficient and can be tailored to the specific needs of each warehouse area.

By understanding the various considerations in high-bay warehouse construction, companies can make more informed decisions about their storage infrastructure, ensuring operational efficiency and competitiveness in an ever-evolving business landscape.

Post Comment