Complete Guide to Cold Storage Warehouse Construction

Learn the ins and outs of cold storage warehouse construction, cooling systems, storage types, and practical examples in this comprehensive article.

Cold storage warehouse construction is a crucial aspect of the modern food and logistics industry. This article delves deep into the construction process, cooling systems, and various types of cold storage warehouses.

From the main components of cooling systems to real-world implementation examples, readers will gain a comprehensive understanding of the latest cold storage technologies.

Whether you’re a professional in this industry or just interested in learning more, this complete guide to cold storage warehouse construction will provide valuable insights and practical information you need.

1.Overview of Cold Storage Warehouse Construction

Cold storage warehouse construction is a complex process that requires careful planning and high technical expertise. The main goal is to create a controlled environment with low temperatures to maintain quality and extend the shelf life of various products, especially food items.

In the construction process, several key aspects must be considered:

- Insulation: The use of high-quality insulation materials is crucial for maintaining internal temperature and energy efficiency.

- Cooling system: Selection and installation of the right cooling system is the heart of a cold storage warehouse.

- Humidity control: Besides temperature, humidity levels must also be carefully regulated to prevent ice formation and maintain product quality.

- Special flooring: Floors must be designed to withstand heavy loads and resistant to low temperatures.

- Doors and seals: Doors must have perfect seals to prevent cold air leakage.

- Ventilation system: Good air circulation is important to maintain even temperature throughout the room.

- Lighting: The lighting system must be efficient and resistant to low temperatures.

- Security and safety: Safety features such as temperature alarms, emergency doors, and fire prevention systems must be integrated.

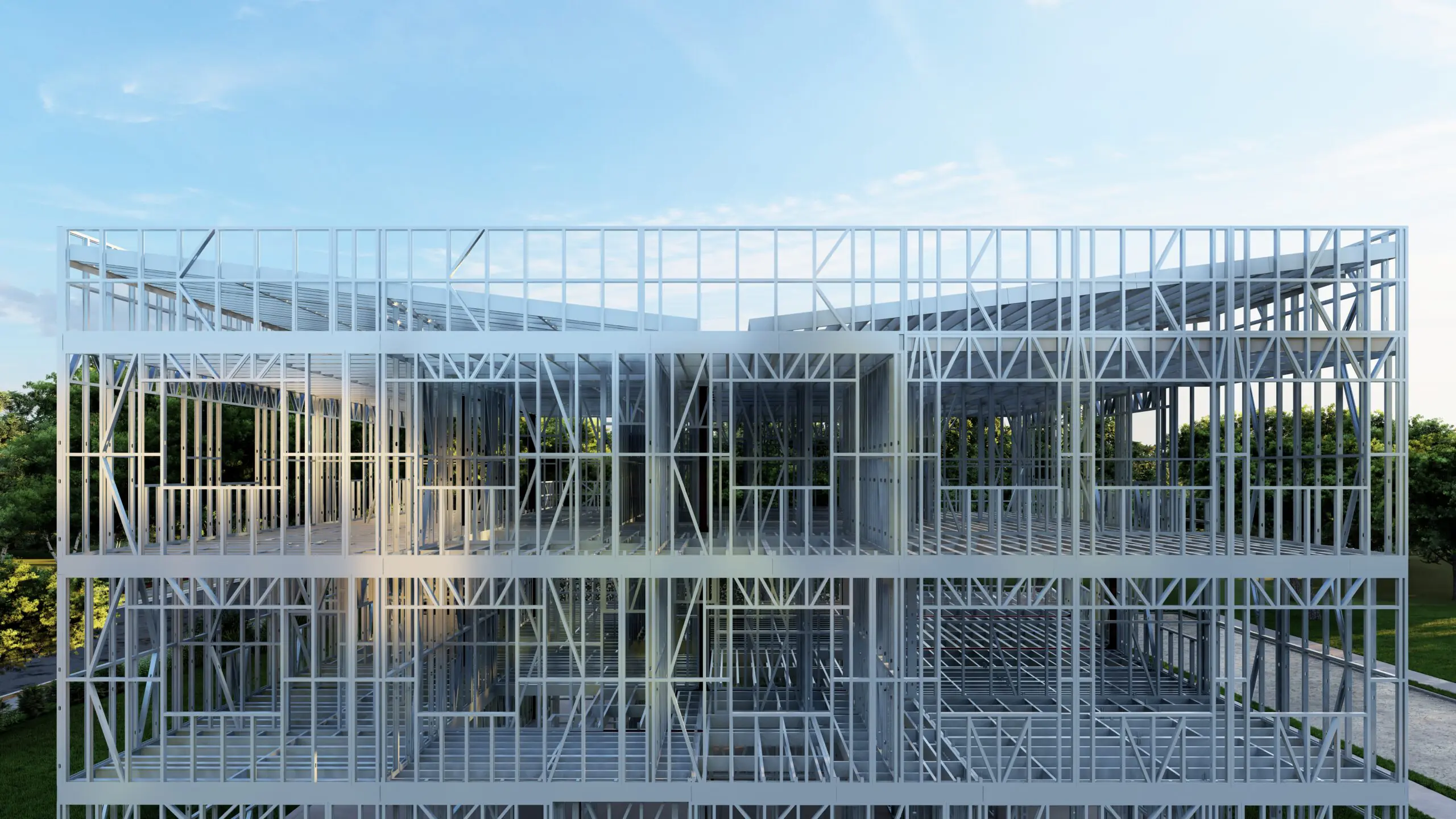

The construction process typically involves the following stages:

- Planning and design

- Site preparation

- Basic structure construction

- Insulation system installation

- Cooling system installation

- Interior and exterior finishing

- Control and monitoring system installation

- Testing and commissioning

Cold storage warehouse construction requires a large investment, but with proper planning and execution, it can provide significant added value for businesses in various industrial sectors.

2.How Do Cold Storage Warehouses Work?

Cold storage warehouses operate based on thermodynamic principles and heat transfer. The main objective is to keep the internal temperature low and stable to maintain the quality of stored products. The cooling system used in cold storage warehouses consists of several main components that work synergistically to achieve and maintain the desired temperature.

Main Components of Cold Storage Warehouse Cooling System:

- THE COOLANT The coolant, also known as refrigerant, is a key substance in the cooling system. Its main function is to absorb heat from the cooled environment and expel it outside. Common coolants include ammonia (R717), freon (R134a, R404A), and CO2 (R744). The choice of coolant depends on factors such as efficiency, environmental impact, and safety.

- THE COMPRESSOR The compressor is the “heart” of the cooling system. Its function is to pump and compress the coolant in gas form, increasing its pressure and temperature. This process prepares the coolant to release heat to the outside environment. There are several types of compressors used, such as reciprocating, screw, or scroll compressors, depending on the scale and specific needs of the warehouse.

- THE CONDENSER After leaving the compressor, the hot and high-pressure coolant enters the condenser. Here, the coolant releases heat to the outside environment, usually through heat exchange with air or water. During this process, the coolant changes from gas to liquid. Condensers can be air-type (with fans) or water-type (using cooling towers).

- THE RECEIVER The receiver functions as a temporary storage place for liquid coolant coming out of the condenser. This component ensures a stable supply of coolant to the evaporator and helps accommodate fluctuations in cooling needs.

- THE SEPARATOR The separator plays an important role in separating liquid from coolant vapor. This is important to ensure that only coolant in the right phase enters various system components, increasing efficiency and preventing damage to components such as compressors.

- THE EVAPORATOR The evaporator is where the actual cooling process occurs. Low-pressure liquid coolant enters the evaporator and absorbs heat from the surrounding air, turning into gas in the process. This cooled air is then circulated throughout the storage warehouse. Evaporators are usually equipped with fans to help distribute cold air.

The working process of this system takes place in a continuous cycle:

- The coolant is compressed by the compressor.

- Heat is released in the condenser.

- The coolant is cooled and condensed into liquid.

- The liquid coolant flows through the expansion valve, lowering its pressure and temperature.

- In the evaporator, the coolant absorbs heat and cools the room.

- The coolant gas returns to the compressor, and the cycle repeats.

This entire process is controlled by an advanced control system that monitors temperature, humidity, and other parameters, adjusting system operation to maintain optimal conditions. Energy efficiency is also an important consideration, with various technologies such as heat recovery systems and the use of variable speed drives on compressors to optimize energy consumption.

3.How Many Types of Cold Storage Are There?

In the cold storage industry, there are two main types that are widely used, each designed to meet the specific needs of various products:

3.1 Refrigerated Cold Storage

Refrigerated cold storage is designed to keep products at temperatures above freezing point, typically between 0°C to 10°C (32°F to 50°F). This type of storage is ideal for:

- Fresh fruits and vegetables

- Dairy products

- Fresh meat and fish

- Processed foods with short shelf life

- Certain medications

The main advantage of refrigerated storage is its ability to extend product shelf life without significantly altering structure or texture. This system is also generally more energy-efficient compared to frozen storage.

3.2 Frozen Cold Storage

Frozen cold storage operates at temperatures below 0°C (32°F), typically ranging from -18°C to -40°C (0°F to -40°F) or even lower for ultra-low temperature storage. This type of storage is suitable for:

- Frozen meat and fish

- Ice cream and other frozen foods

- Raw food ingredients for long-term storage

- Certain pharmaceutical products that require very low temperatures

Frozen storage allows for very long-term storage of products, even up to several years for some types of products. However, the freezing process can alter the texture and sometimes the quality of products, especially for fresh fruits and vegetables.

In addition to these two main types, there are also variations and combinations used in the industry, such as:

- Controlled atmosphere (CA) storage: In addition to temperature, the gas composition in the storage space is also regulated to extend the shelf life of certain products, especially fruits.

- Humidity-controlled storage: Regulates humidity levels for products sensitive to humidity changes.

- Multi-temperature storage: Facilities that have several zones with different temperatures to accommodate various types of products in one location.

The choice of the right type of cold storage depends on the type of product, required storage duration, and logistical and economic considerations. By understanding the specific characteristics and needs of products, industry players can maximize the efficiency and effectiveness of their cold storage operations.

4.Five Cold Storage Warehouse Examples

4.1 Private Cold Storage

Private cold storage is a facility owned and operated by a specific company to store their own products. Examples:

- Large ice cream manufacturers that have frozen storage warehouses to store their products before distribution.

- Meat companies that have refrigerated facilities to store fresh and frozen meat.

Advantages:

- Full control over operations and security

- Can be customized to the company’s specific needs

- Potential for long-term cost savings

Challenges:

- Large initial investment

- Full responsibility for maintenance and operations

4.2 Public Cold Storage

Public cold storage is a facility that rents storage space to various customers. Examples:

- Large distribution centers that provide cold storage services for various food and beverage companies.

- Logistics facilities offering refrigerated storage for pharmaceutical products.

Advantages:

- Flexibility in storage capacity

- No need for large infrastructure investments

- Access to the latest expertise and technology

Challenges:

- Ongoing rental costs

- Less control compared to private facilities

4.3 Refrigerated Containers

Refrigerated containers are portable cold storage units often used for transportation and temporary storage. Examples:

- Refrigerated containers at ports for storing products before loading onto ships.

- Portable cold storage units at construction sites for storing food ingredients.

Advantages:

- High portability

- Can be used for temporary or permanent storage

- Easy scalability

Challenges:

- Limited capacity compared to large warehouses

- May be less energy efficient for long-term storage

4.4 Blast Freezers

Blast freezers are a special type of cold storage warehouse designed to freeze products very quickly. Examples:

- Fish freezing facilities at fishing ports.

- Frozen food factories using blast freezers to freeze fresh vegetables.

Advantages:

- Rapid freezing maintains product quality

- Ideal for products requiring immediate freezing after harvest or production

Challenges:

- High energy consumption

- Usually used only for the freezing process, not long-term storage

4.5 Ultra-Low Temperature Cold Storage

Ultra-low temperature cold storage is designed to maintain very low temperatures, typically below -80°C. Examples:

- Storage facilities for COVID-19 vaccines require very low temperatures.

- Research laboratories storing biological samples at ultra-low temperatures.

Advantages:

- Enables long-term storage for highly sensitive products

- Essential for certain medical and scientific applications

Challenges:

- Very high energy consumption

- Requires special equipment and safety procedures

Each type of cold storage warehouse has its own unique characteristics and applications. The choice of the right type depends on the type of products stored, storage volume, storage duration, and specific industry or company needs. By understanding the advantages and challenges of each type, industry players can make the right decisions for their cold storage needs.

5.Conclusion

Cold storage warehouse construction is a vital aspect of the modern supply chain, especially for the food, beverage, and pharmaceutical industries. The complexity of building and operating these facilities reflects their important role in maintaining product quality and safety.

From the above discussion, we can conclude several key points:

- An efficient and reliable cooling system is the heart of every cold storage warehouse. Components such as coolant, compressor, condenser, and evaporator must work harmoniously to maintain the desired temperature.

- There are various types of cold storage, ranging from refrigerated storage to frozen storage, each designed to meet the specific needs of various products.

- The choice between private, public, or portable solutions such as refrigerated containers depends on the scale of operations, required flexibility, and financial considerations.

- Technology continues to evolve in this industry, with innovations such as blast freezers and ultra-low temperature storage enabling special applications and storage of highly sensitive products.

- Energy efficiency and sustainability are becoming the main focus in the design and operation of modern cold storage warehouses, given the high energy consumption required.

With technological developments and increasing need for safe and efficient storage, the cold storage warehouse construction industry will continue to evolve. Innovations in insulation materials, more efficient cooling systems, and the integration of smart technology will shape the future of this industry.

For business players and professionals in this field, a deep understanding of various aspects of cold storage warehouse construction and operation is essential. With this knowledge, they can make the right decisions to meet their storage needs, optimize operations, and ultimately provide added value for customers and end consumers.

Post Comment