Steel Structure Quality Control Procedures

Learn effective quality control procedures for steel structures to ensure the long-term safety and durability of your buildings.

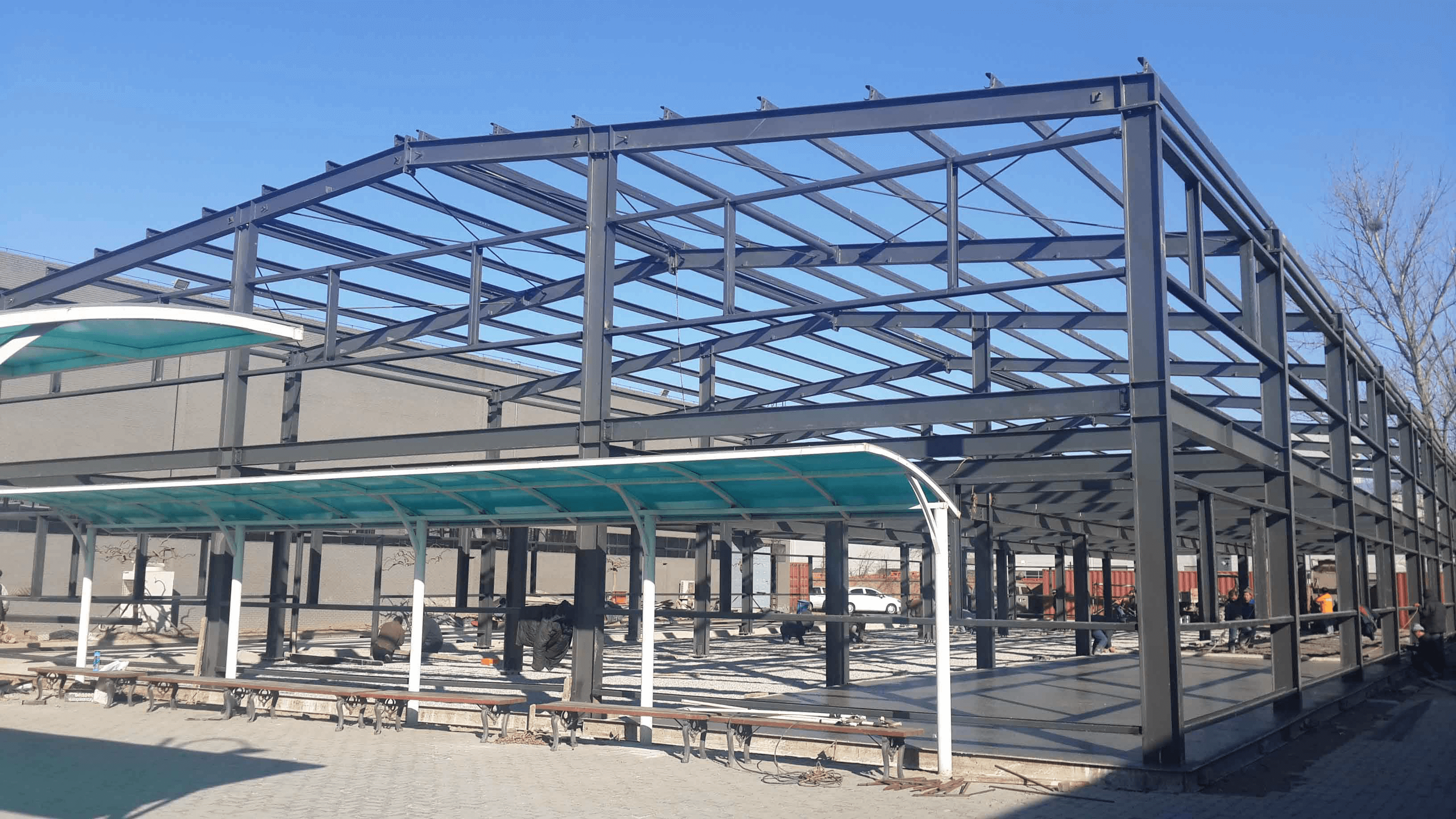

Quality control in steel structure construction is a crucial aspect that cannot be overlooked. This article will comprehensively discuss steel structure quality control procedures, from the importance of this process to the detailed steps that need to be followed.

By understanding and implementing proper quality control procedures, we can ensure the safety, durability, and efficiency of steel structures in the long term. Let’s explore further how to implement effective quality control in your steel structure construction project.

1. A Brief Introduction to Quality Control in Construction

Quality control in construction is a series of processes designed to ensure that every aspect of construction meets established standards and specifications. In the construction industry, quality control encompasses various activities, from raw material inspection to final structure testing.

The main objective of quality control is to prevent defects or failures in construction, and to ensure that the resulting building is safe, functional, and meets client expectations. This process involves various parties, including engineers, project managers, and specialised quality control teams.

In the context of steel structures, quality control becomes increasingly important given the vital role of steel as the primary material in various types of buildings, from skyscrapers to bridges.

2. The Importance of Quality Control in Steel Structure Construction

2.1 Safety

Safety is the most critical aspect of any construction project, especially in steel structures. Strict quality control ensures that every component of the steel structure meets established safety standards.

This includes checking material strength, joint integrity, and overall structural stability. Without adequate quality control, the risk of structural failure increases significantly, which can result in fatal accidents, serious injuries, or extensive property damage.

Furthermore, quality control also helps in identifying and addressing potential safety issues from the early stages.

Moreover, good quality control also ensures that the steel structure can withstand expected loads, including wind loads, earthquakes, and other dynamic loads, thus enhancing the overall safety of the building.

2.2 Durability

The durability of steel structures greatly depends on the quality of materials and construction. Effective quality control ensures that the steel structure is not only strong when completed but also able to maintain its integrity for years to come. This involves thorough inspection of steel material properties, including tensile strength, hardness, and corrosion resistance.

The quality control process also includes inspection and testing of welded and bolted connections, which are critical points in steel structures. High-quality joints will ensure that the structure remains stable and resistant to various stresses and vibrations throughout its service life.

Additionally, quality control also includes inspection of corrosion protection, such as galvanising or painting, which is crucial for extending the life of steel structures, especially in aggressive environments or exposed to extreme weather.

By ensuring long-term durability, quality control helps reduce the need for expensive maintenance and repairs in the future, as well as extending the overall lifespan of the steel structure.

2.3 Cost efficiency

Although implementing strict quality control procedures may require a higher initial investment, it actually results in significant cost efficiency in the long run. By detecting and addressing problems early in the construction process, quality control prevents the need for expensive repairs or even reconstruction later on.

Moreover, high-quality steel structures require less routine maintenance and have a longer service life, meaning long-term cost savings for building owners. Quality control also helps optimise material use, reduce waste, and improve the overall efficiency of the construction process.

This can result in significant cost savings in terms of materials, labour, and project time. Furthermore, the good reputation resulting from consistent construction quality can bring more business opportunities, which in turn increases the long-term profitability of construction companies.

2.4 Regulatory compliance

Compliance with regulations and industry standards is a crucial aspect of steel structure construction. Quality control plays a vital role in ensuring that every aspect of construction meets, or even exceeds, applicable legal and regulatory requirements.

This includes compliance with local and national building codes, workplace safety standards, and environmental regulations. Without strict quality control procedures, the risk of regulatory violations increases, which can result in hefty fines, project stoppages, or even legal action.

Quality control also assists in the documentation required to demonstrate regulatory compliance. This includes keeping detailed records of material specifications, test results, and certifications. Good documentation is not only important for regulatory inspections and audits but also valuable in cases of litigation or insurance claims.

Furthermore, by consistently meeting or exceeding regulatory standards, construction companies can build a strong reputation among regulators and clients. This can facilitate the approval process for future projects and increase stakeholder confidence in the company’s ability to complete projects safely and to standard.

2.5 Reputation

Reputation is an invaluable intangible asset in the construction industry. Consistent and effective quality control in steel structure construction contributes significantly to building and maintaining a company’s positive reputation.

High and consistent quality creates trust among clients, which can result in repeat business and recommendations. In a highly competitive industry, a reputation for superior quality can be a key differentiating factor that helps companies win new contracts and attract high-quality clients.

Moreover, a good reputation also positively impacts relationships with other stakeholders, including regulators, suppliers, and business partners. This can result in more favourable conditions in contract negotiations, better access to prestigious projects, and even opportunities to participate in innovative or high-risk projects.

Furthermore, a strong reputation for quality can help attract and retain skilled workforce, which is crucial in the construction industry. Employees tend to be more proud and committed when working for companies known for their high quality standards, which in turn can increase productivity and innovation within the organisation.

3. Quality Control Procedures in Steel Structure Construction

3.1 Material inspection

Material inspection is a crucial first step in the quality control procedures for steel structures. This process begins with verification of the steel material certificates received from suppliers. These certificates must include detailed information about the chemical composition, mechanical properties, and production process of the steel. The quality control team will verify that the specifications listed in the certificate comply with project requirements.

Next, independent testing is conducted to ensure the accuracy of the information in the certificates. This involves taking samples from each batch of material received. These samples are then tested in the laboratory to determine chemical composition using methods such as optical emission spectroscopy. Mechanical properties such as tensile strength, yield strength, and elongation are also tested using universal testing machines.

Visual inspection is also an important part of this process. Experienced inspectors will examine the steel surface to detect defects such as cracks, deep scratches, or deformations. They will also check the dimensions and tolerances of the steel to ensure compliance with specifications. If inconsistencies or defects are found, the material will be rejected or segregated for further evaluation. This thorough material inspection process becomes the foundation for ensuring the overall quality of the steel structure.

3.2 Fabrication process control

Fabrication process control is a critical stage in ensuring the quality of steel structures. It begins with dimensional and tolerance inspection of each produced component. Accurate measurements are made using precision tools such as micrometres and digital callipers. Any deviation from design specifications is noted and evaluated to determine whether the component can be accepted or requires repair.

Welding process supervision is another important aspect of fabrication control. This involves verifying welder qualifications, inspecting welding procedures, and direct supervision during the welding process. Inspectors will ensure that welding parameters such as current, voltage, and welding speed comply with specifications. They will also visually inspect weld results to detect defects such as porosity, cracks, or inadequate penetration.

Bolt joint inspection is also an integral part of fabrication control. This involves verifying that the size, grade, and number of bolts comply with design specifications. Bolt tightening torque is checked using calibrated torque wrenches to ensure adequate joint strength. Additionally, inspections are carried out to ensure that bolt holes are properly aligned and there is no damage to the bolt threads.

The entire fabrication process is documented in detail, including any deviations and corrective actions taken. This documentation is important for quality audits and as a reference for future maintenance.

3.3 Non-destructive testing

Non-destructive testing (NDT) is a series of methods used to evaluate the integrity of steel structures without damaging them. One of the most commonly used methods is ultrasonic testing. In this method, high-frequency sound waves are transmitted through the steel material. Changes in the returning wave pattern can indicate the presence of internal defects such as cracks or inclusions. Ultrasonic testing is very effective for detecting defects that are not visible to the naked eye and is often used to inspect critical weld joints.

Magnetic particle testing is another method frequently used, especially for detecting surface defects in ferromagnetic materials. In this process, the steel component is magnetized and fine magnetic particles are sprayed onto the surface. If there are defects, these particles will gather around the defect area, forming visual indications that can be interpreted by trained inspectors.

Radiographic testing uses X-rays or gamma rays to produce internal images of the steel structure. This method is very effective for detecting internal defects, especially in thick weld joints. However, due to radiation risks, the use of this method requires strict safety procedures and is only performed by certified personnel.

Other NDT methods include penetrant testing for surface defects and eddy current testing for detecting near-surface defects. The selection of the appropriate NDT method depends on the type of material, potential defect location, and the level of sensitivity required. The results of all non-destructive testing are documented in detail and become part of the project’s quality control records.

3.4 Assembly inspection

Assembly inspection is a critical stage in ensuring that all steel structure components are properly installed according to the design. This process begins with alignment verification and conformity with technical drawings. Inspectors use various precision measuring tools, including laser trackers and total stations, to ensure that each component is in the correct position. Alignment tolerances are usually very tight, often in the millimetre range, to ensure structural integrity and optimal performance.

Bolt tightness inspection is another important aspect of assembly inspection. Each bolt joint is inspected to ensure that the number, size, and grade of bolts comply with specifications. Bolt tightness is verified using methods such as turn-of-nut or tension control bolts. In some cases, ultrasonic testing is also used to verify bolt tension. Joints that do not meet specified tightness standards must be re-tightened or, if necessary, replaced.

Paint and protective coating quality control is also an integral part of assembly inspection. This involves inspecting surface preparation before painting, verifying wet and dry paint thickness, and visual inspection for defects such as runs, sags, or holidays in the paint layer. Adhesion testing is also conducted to ensure that the protective coating will last for the expected lifespan of the structure.

During the assembly inspection process, any non-conformities or issues are noted and reported for corrective action. Complete documentation of the inspection process, including photos and measurements, is kept as part of the project records. This thorough assembly inspection ensures that the final steel structure meets all design specifications and required quality standards.

3.5 Load testing

Load testing is the final and crucial stage in verifying the overall performance of the steel structure. Static load tests are conducted to ensure that the structure can withstand the specified design loads without unacceptable deformation or damage. In this testing, pre-calculated loads are gradually applied to the structure, while deformation and stress are monitored using various sensors and measuring devices. Strain gauges are used to measure local strain, while displacement transducers measure global structure deflection.

Data collected during static load testing is compared with structural analysis predictions to verify that the structure behaves as expected. If there are significant differences between actual and predicted behaviour, further analysis is required to determine the cause and whether corrective action is needed.

Dynamic testing is also often conducted, especially for structures expected to experience moving or cyclic loads, such as bridges or offshore structures. This testing assesses the structure’s response to dynamic loads and may include vibration testing, impact testing, or simulation of wind or earthquake loads. Accelerometers and vibration sensors are used to measure the structure’s dynamic response.

The results of load testing are thoroughly analysed and compared with performance criteria set in the design specifications. If the structure meets or exceeds these criteria, this provides final confirmation that the structure is safe for use and will function as expected throughout its service life. Complete documentation of testing procedures, results, and analysis is kept as part of the project records and can be used as a reference for future maintenance and inspections.

3.6 Documentation and reporting

Comprehensive documentation and reporting are vital components in the quality control procedures for steel structures. This process begins at the start of the project and continues until the completion of construction. Each stage of quality control, from material inspection to final load testing, must be documented in detail. This includes recording the results of all inspections and tests, including dates, methods used, personnel involved, and results obtained.

Documentation should include material certificates, laboratory test reports, visual inspection results, non-destructive testing data, project photos, and records of any deviations or problems encountered during the construction process. All these documents should be well-organised and easily accessible for future reference.

Compiling a comprehensive quality control report is the next important step. This report should provide an overview of the quality control process, including a summary of all inspections and tests conducted, results obtained, and conclusions regarding the overall quality of the structure. The report should also list any areas requiring special attention or future monitoring.

Follow-up and corrections for any non-conformities found during the quality control process should also be documented in detail. This includes a description of the problem, corrective actions taken, and verification that repairs have been carried out correctly and effectively.

An effective document management system is essential to ensure that all this information can be easily and securely accessed. This may involve the use of an electronic document management system that allows for quick searches and document version tracking. Good documentation is not only important for ensuring the current quality of the structure but also valuable for long-term maintenance, future inspections, and as a reference for subsequent projects.

Post Comment